Sand Blasting in Charleston, SC

What is Sand Media Blasting?

Sand media blasting is a highly effective method for cleaning and preparing a variety of surfaces, ranging from metal and concrete to wood. The technique involves the use of compressed air to propel fine sand particles at high speeds towards the targeted area. These sand particles act as a high-grit abrasive that scours away contaminants like paint, rust, and grime. Unlike some other cleaning methods, sand media blasting is particularly useful for dealing with tough or stubborn material that can't easily be removed by scrubbing or washing. By adjusting the pressure and sand grain size, the method can be tailored to fit specific needs, making it a versatile option for both industrial and residential projects.

Benefits of Sand Media Blasting

When it comes to surface preparation and cleaning, sand media blasting offers a range of advantages that set it apart from other methods. Below are some key benefits that make it a go-to choice for many.

Efficient Cleaning: Removes even tough grime and coatings

Sand media blasting is highly efficient in removing stubborn substances like grime, rust, or paint. This makes it an excellent option for projects that require a deep clean or surface preparation prior to painting or coating.

Versatile: Suitable for a range of surfaces, from metal to concrete

One of the standout features of sand media blasting is its versatility. It can be used effectively on a wide variety of surfaces including metal, concrete, wood, and even certain types of plastic, allowing for broad applicability across different projects.

Environmentally Safer: Uses natural sand particles

In a world increasingly concerned with environmental impact, sand media blasting stands out as a greener option. The method utilizes natural sand particles, which are less harmful to the environment compared to chemical cleaners or synthetic abrasives.

Sand media blasting is an efficient, versatile, and environmentally safer option for surface cleaning and preparation. These advantages make it a reliable choice for a wide range of residential and industrial applications

Our Process

When you choose our sand media blasting services, you're selecting a thorough, well-planned process that prioritizes both effectiveness and safety. Here's a breakdown of the steps we meticulously follow to deliver the best results:

1. Safety Measures

Before initiating any blasting project, we take all necessary safety precautions to protect both our technicians and your property. This involves wearing appropriate protective gear and securing the area to prevent any accidental damage or injuries.

2. Equipment Setup

Setting up the sand media blasting equipment is a crucial step for ensuring an efficient and effective process. Our team carefully calibrates the machines, adjusting pressure and sand particle size to suit the specific requirements of your project.

3. Surface Preparation

Preparing the surface is vital for achieving the desired outcome. We take the time to assess the area that needs treatment, removing any obstacles and masking off sensitive sections to prevent unintended abrasion.

4. Blasting Procedure

The actual blasting procedure is carried out with precision, as our trained technicians skillfully aim the compressed air and sand mixture at the targeted areas. This ensures that all contaminants, such as rust, paint, or grime, are effectively removed.

5. Final Inspection

Once the blasting is complete, we conduct a thorough final inspection to verify that all objectives have been met. We also ensure that the area is cleaned, and any debris is properly disposed of, leaving your space neat and ready for use.

In conclusion, our detailed, five-step process ensures that every sand media blasting project we undertake is executed to the highest standards, from initial safety measures to final inspection. This systematic approach ensures that we meet your specific needs while prioritizing safety and efficiency.

Safety Measures

At the heart of our operation is a strong commitment to safety for both our team and your property. Our technicians undergo rigorous training to stay current with the most recent safety standards and protocols in the sand media blasting industry. This not only equips them with the technical know-how but also ingrains a culture of safety that permeates every project we handle. Before starting any job, staff members are outfitted with all the necessary protective gear, including masks, gloves, and suits, to minimize any risk of injury. By taking these thorough safety measures, we aim to create a secure environment that instills confidence while ensuring that the project is completed to the highest safety specifications.

Got a Question? We’re Here to Help.

You can arrange an appointment or make an enquiry by phone or email, orget in touch to us via our contact form.

Frequently AskED Questions

Take a moment to read answers to our most frequently asked questions about our services.

Cities We Proudly Service

Click on the dropdown below to see all the cities we provide sand blasting contracting services.

Contact EAS Environmental Today!

EAS Environmental will do everything we can to ensure your experience with us is excellent.

Request A FREE Estimate

Request a Free Estimate Form

24-Hour Emergency Service

Contact Information

Phone: 843-460-8391

Address: 125 Bud Lane Ladson Charleston, SC 29486

Email: sturner@easenvironmental.com

Business Hours:

24/7 Open

Appointments Available

Servicing North Charleston and all of South Carolina

EAS Environmental provides many services related to environmental hazardous abatement and cleanup as well as solving moisture control issues.

Related Services

Please see our most requested services listed below. EAS Environmental is here for you when you need asbestos or lead abatement, or moisture control service to prevent mold growth.

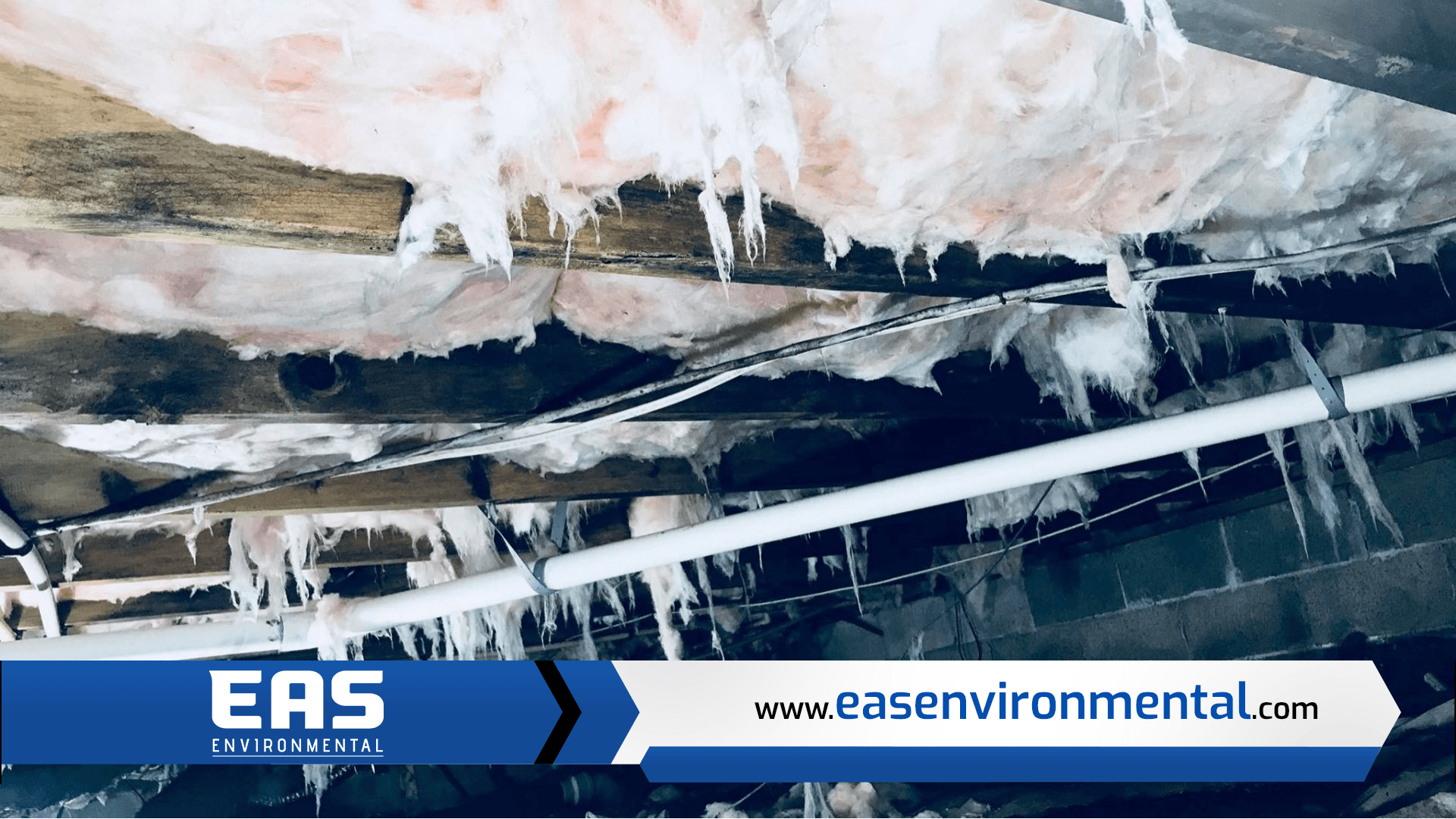

Asbestos Removal

With asbestos removal services, you'll never again have to worry about this hazardous substance that could wreak havoc on your health and wellbeing. Whether its in a private residence or commercial setting, we're a licensed and certified abatement firm that will remove asbestos from anywhere it may be found!

Demolition Services

It's hard to find a good demolition company, especially if you're in an emergency situation. We are the best demolition company around, and we can handle any job big or small. Our team of experts have years of experience under their belt so they'll be able to get your project done right the first time.

Disaster Restoration: Fire and Water Damage Restoration

When disaster strikes, fast action is critical. If your home or business has suffered fire or smoke damage, don’t wait—EAS Environmental is here to help. Our expert team provides responsive and prompt fire and damage restoration services to help you recover quickly and safely. Call us today to learn more about our fire damage repair services near you!

Schedule Your FREE Asbestos & Lead Evaluation!

Did you know that asbestos containing materials are still being sold in today? Call us today to find out more!